It may not be common knowledge that Meijer Handling Solutions pioneered the development of hydraulic extendable KOOI® ReachForks, but since the development of these telescopic forks in 1980, the Friesland-based company has now produced more than 100,000 pairs of telescopic forklift forks. This is an impressive number.

Many thousands of forklifts of different brands are equipped with these telescopic forks, providing a more efficient way of handling loads from one side (about 50% faster than from two sides) and allowing more than 30% more pallets to be stored in a warehouse with double-deep storage systems. When different pallet sizes are used, telescopic forks provide the flexibility needed to handle various types of pallets, increasing the efficiency and safety of forklift operations.

Obviously, with the production of over 100,000 ReachFork sets, a double amount of forks is needed. The inner forks must be of excellent quality to ensure the safety of the ReachForks and be suitable for the many production steps the ReachFork must go through.

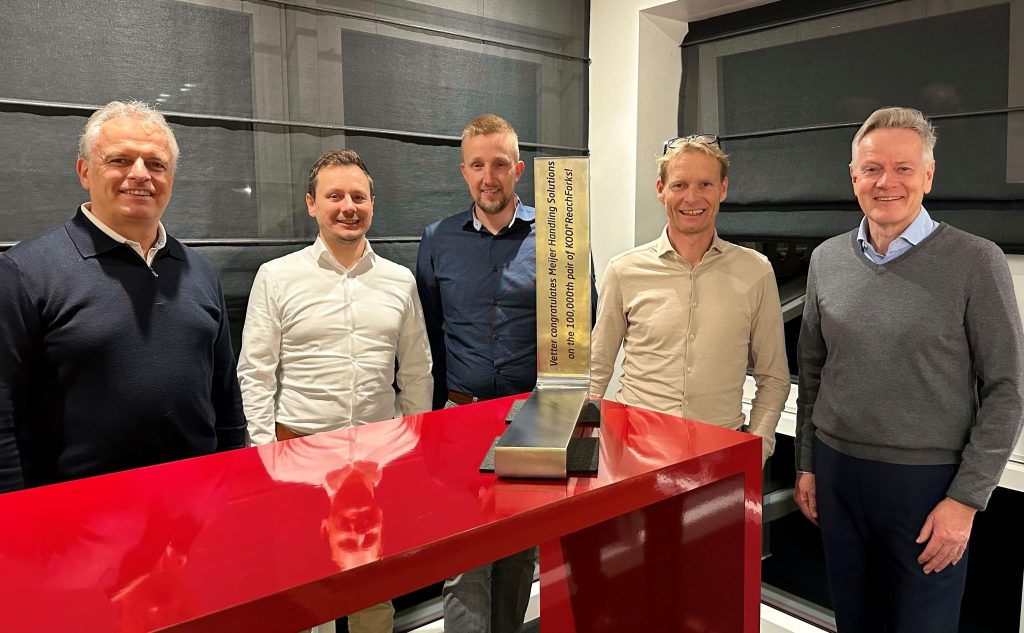

This is where the long-standing partnership with Vetter comes into play. Vetter supplies high-quality inner forks to meet the rigorous standards required for Meijer’s production process. Meijer and Vetter have worked closely together for decades, and during a visit to the factory in Germany, Vetter surprised Meijer with a wonderful memento.

.custom_postmeta {

margin-bottom:0px;

}

.mk-social-share ul {

display:flex;

justify-content: space-evenly;

list-style:none;

margin: 0 0 2em 0;

}

.mk-about-author-wrapper .about-author-name {

padding: 10px 0 0 0;

text-align: center;

}