The automotive industry is faced with unparalleled material handling challenges. Load carriers range from various pallet sizes to numerous types of metal bins and specialized transportation racks for stamped components.

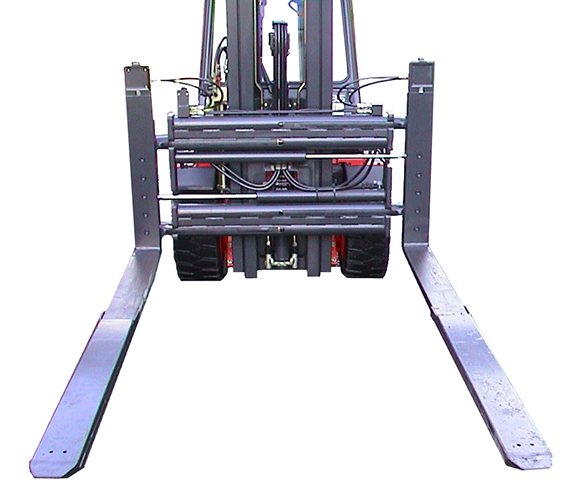

VARIABLE LENGTH AND WIDTH

Most steel containers have insert pockets for the lift truck forks but the position of those pockets are rarely the same. This means the distance measured over the forks often requires frequent readjustment. Since the depth of the loads, (cages, boxes, bins, etc…), varies as much as the width, the fork length required for safe support and transport also varies and often requires lift trucks with different sized fork lengths. The extra time and equipment needed to deal with these challenges escalates operational costs.

THE PERFECT COMBINATION!

The solution for this handling problem is quite simple. By combining a forks-positioner or forks-spreader withhydraulic-telescopic KOOI-REACHFORKS®, both width over the forks and length of forks can be adjusted at the touch of a lever. Depending on the application and if there is less frequent need for variable fork length,Manual Extendable KOOI-REACHFORKS® can also be used.

IMPROVED EFFICIENCY AND SAFETY

The combination of forks spreading and fork extensions saves time, improves operational safety and can reduce the number of forklift trucks needed within the operation. Having the ability to quickly adjust the fork length also helps prevent damage to load carriers and to product as the correct fork length is always available.

Telescopic forks can also save time in loading/off-loading operations as flatbed trailers or rail cars can be accessed from just one side.