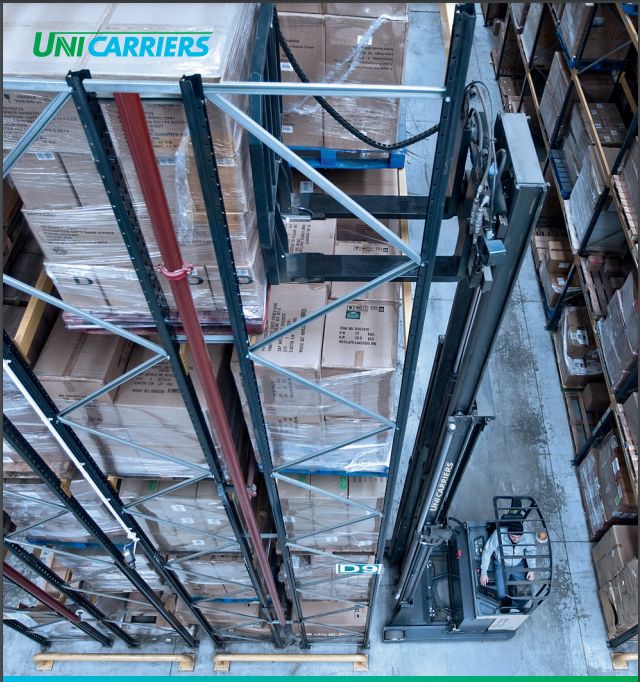

Since the invention of telescopic forks in 1980, Meijer Handling Solutions revolutionized the material handling industry by offering a highly efficient solution for double-deep pallet storage. Over the decades, these innovations have allowed thousands of forklifts worldwide to be equipped with KOOI® telescopic forks, enhancing storage capacity and operational efficiency in warehouses. These forks are designed explicitly for double-deep pallet storage, making them ideal for warehouses.

We found this nice brochure which clearly explains why using telescopic forks for double-deep storage can significantly increase warehouse capacity and improve storage efficiency by up to 30% compared to traditional “single-deep” operations.

Brochure Unicarriers: Click here

.custom_postmeta {

margin-bottom:0px;

}

.mk-social-share ul {

display:flex;

justify-content: space-evenly;

list-style:none;

margin: 0 0 2em 0;

}

.mk-about-author-wrapper .about-author-name {

padding: 10px 0 0 0;

text-align: center;

}