RollerForks® provide major US cereal manufacturer with payback in less than 90 days!

Their goal was to reduce costs associated with receiving corrugated packaging materials that were shipped on wooden pallets. “Palletless” shipping meant they could eliminate the cost of in-bound pallets and simply transfer the goods to existing pallets designed for their storage system. The challenge: to find the right equipment to do so.

They initially considered a hydraulic push-pull type attachment, but their existing forklift truck fleet consisted of leased trucks, none of which offered the additional capacity or hydraulic functions needed for this type of attachment.

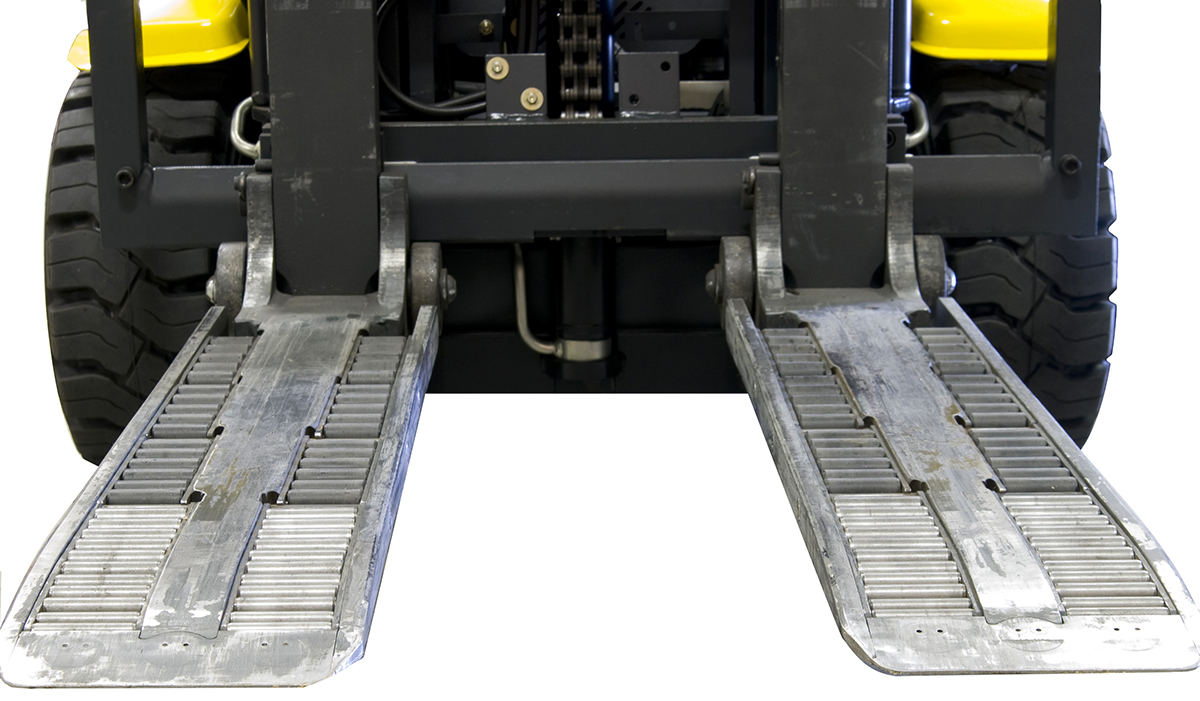

Nissan Lifttrucks of Memphis suggested Meijer Handling Solutions‘ RollerForks®, a simple solution that could quickly be implemented. The RollerForks® replaced the existing forks and allowed for fast and efficient off-loading and palletizing of corrugated bundles, while still offering the versatility to handle standard pallets in other areas. Since they are strictly mechanical, there was no need for modified equipment.

The cost reduction resulting from this simple change: savings of nearly $3000.00 per month! Plus, the payback on their RollerForks® investment was achieved less than 90 days. They also liked the fact that they did not have to invest in equipment they could not retain. Now, the RollerForks can easily be transferred to new forklifts once their current lease expires, and new trucks are brought in.

A simple, cost-effective long-term handling solution.