Cross-docking is a logistics process where products received at a warehouse or distribution center are directly transferred from incoming to outgoing shipping areas without long-term storage. This method minimizes handling time, reduces storage costs, and accelerates the delivery process, making it ideal for time-sensitive goods.

In cross-docking, a variety of goods are presented with associated pallet sizes that often do not conform to standard dimensions. Telescopic forklift forks make a standard forklift much more efficient as the forklift becomes multi-functional, capable of handling multiple pallets at once or transporting long, non-standard pallets without the need for additional tools like the loose extension sleeves to be attached. Fork extender sleeves are not ergonomic, and it takes extra time to mount them, just when time is a determining factor.

Not only standard pallets are handled in cross-docking. With long goods, for example, they must be adequately supported by the forks; otherwise, they can damage the pallet. When forklift forks are too long, they protrude from the back of the pallet, which can also result in damage. With the ReachForks, the length of the forks can always be varied.

Unloading and loading with telescopic forks has many advantages; one or two pallets can be handled at a time as desired, and long, non-standard pallets can also be managed with extendable forks, eliminating the need to install separate “add-on sleeves.” With the ReachForks, there is less disruption in the unloading/loading process, benefiting overall efficiency with ±20% in time.

The choice of an electric pallet truck and or the use of a counterbalance forklift for cross-docking depends on many factors, such as pallet weight, distances to be driven within the warehouse, and pallet variables, among others. Since telescopic forks can be retracted, they are often shorter than standard forklift forks, allowing the forklift to turn into the pallets faster and thereby saving space.

The forklift driver can decide to take one or two pallets to the buffer locations when unloading the truck with ReachForks, depending on the dimensions of the pallets. The significant advantage of carrying two palles at the same time is that pallet A can be placed in its location, and the forklift can immediately continue to pallet location B. With long, non-standard pallets, the forks can be extended eliminating the need to install separate sleeves.

We noted that internal transport vehicles with a fixed fork length are less flexible than those with telescopic extendable forks. The ReachForks reduce the risk of damage, provide adequate support for a load at long lengths, and, optionally, ReachForks can transport one or more pallets simultaneously. Not only is there a time saving, but costs are also reduced in terms of the forklift’s energy consumption and maintenance as the forklift travels fewer meters.

Since the ReachForks can be adjusted to various lengths, the driver can work faster because the preset length of the ReachForks reduces the risk of damage. With a fixed fork length, the driver will have to work more cautiously, and this handling will take more time, and generate more costs.

The ability to lift two pallets with extendable forklift forks depends on the dimensions of the pallets. If one or two Euro pallets need to be handled from the long side, ReachForks, extending from 1000 mm to 1600 mm, could be chosen.

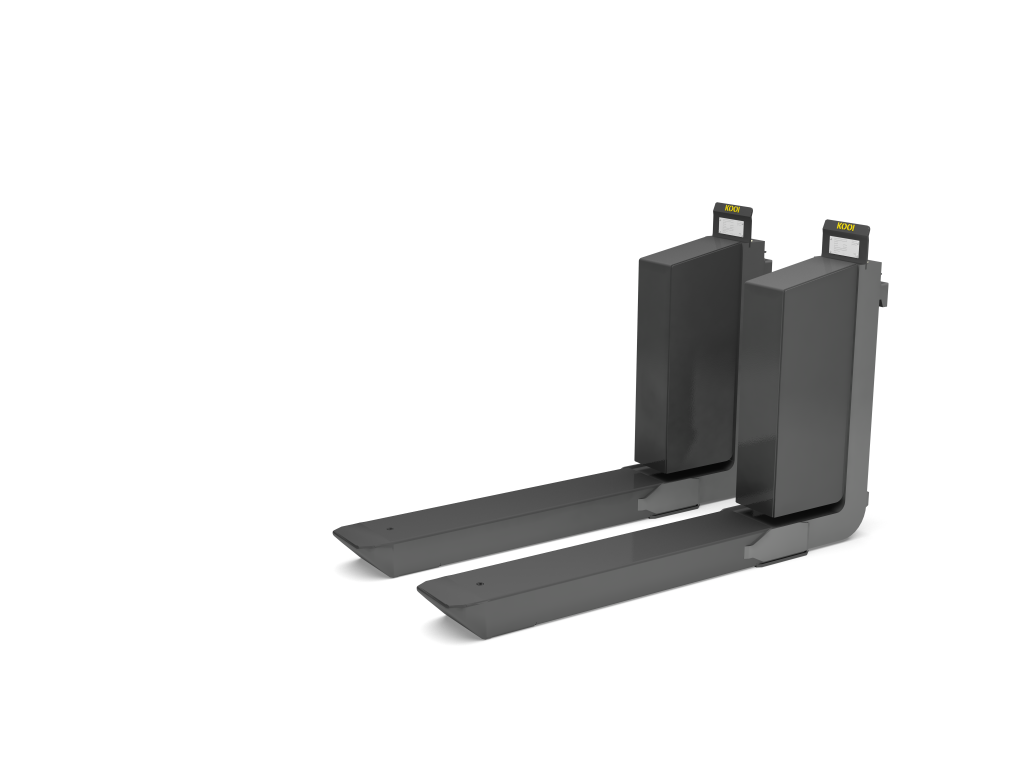

Within the KOOI® ReachForks range, we produce specific models for various applications. For cross-docking, where the primary function of the reach forks is the extension of the forks, we have designed the so-called “Extensions-Range.” In this model, the ReachForks are designed so that the outer sleeves cannot get caught on any cross boards on the underside of the pallet.

The hydraulically extendable forks make it possible to remove one or two pallets at a time from the truck, including non-standard long pallets. This increases unloading efficiency by approximately 20%.

The KOOI® ReachForks can be extended to place one or two pallets at a time into a truck, improving efficiency by up to 37%. This is because the pallets can be optimally grouped and placed directly behind each other in the truck. This results in fewer unnecessary Cross-docking movements and increased overall efficiency in logistics processes.

In most cases, add-on sleeves are unnecessary because both hydraulic and manual KOOI® ReachForks can be for example, extend from 1200 mm to 2000 mm (47.2″ to 78.7″).

Yes, energy consumption in Cross-docking can be reduced by up to 20% because the same forklift can handle two pallets at once, reducing the distance it needs to travel.

Forklifts are often used in cross-docking within B2B (business-to-business) because the goods/pallets offered are often industry-related. Forklift attachments are preferably purchased by the forklift supplier and delivered to the end user as a complete package. The reason for this is that the forklift supplier must have the correct knowledge about the mounting of the attachment and adjust the residual load data of the forklift so that when extending or picking up a load, the forklift is balanced. For more information, you can always contact our importer.