With the KOOI® Next program the forklift can be used even more efficiently. The handling speed can be increased, damage to goods, pallets and racks can be reduced and safety can also be improved. Many companies use temporary workers and under time pressure it becomes more difficult to provide the forklift driver with adequate training. The KOOI® Next program is an excellent tool to provide the driver with that information, so that he quickly becomes familiar with the forklift.

ReachDetect is a compact sensor system that detects the three key states of ReachForks: fully retracted, in motion, and fully extended, enabling precise control, safety, and automation in the material handling industry.

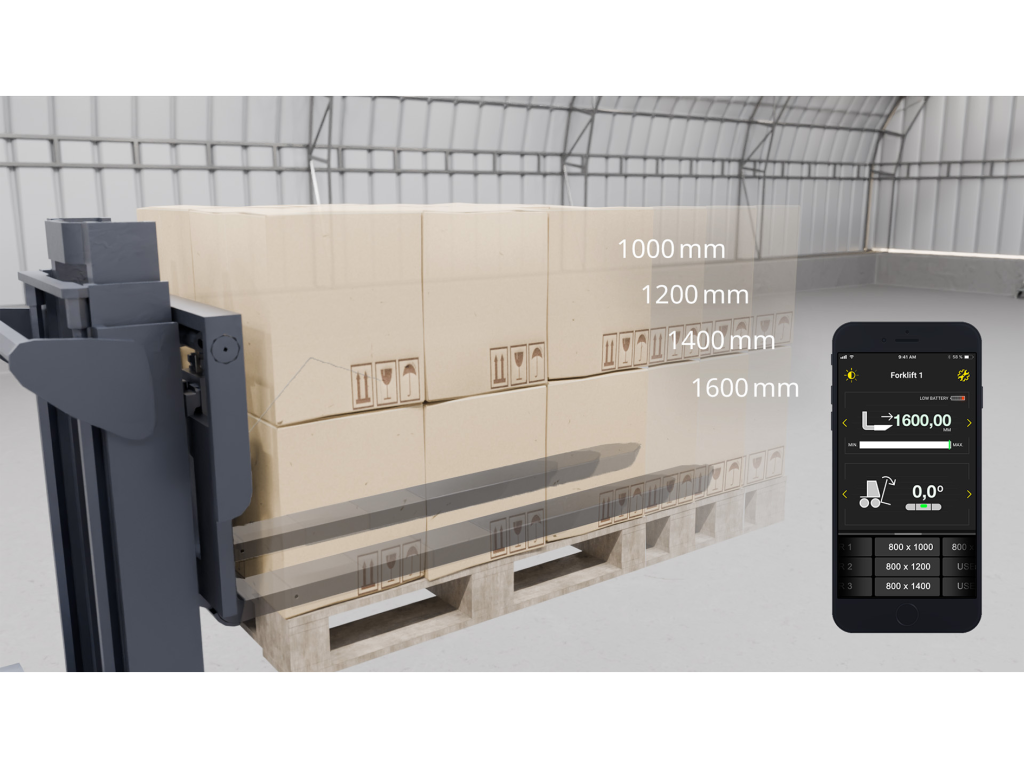

Forklifts such as AGVs and Very Narrow Aisle (VNA) trucks are frequently equipped with telescopic forks. These forks enable special forklift pallets to be placed double-deep in warehouse racks, help bridge certain distances due to new warehouse layout configurations, or serve other logistical needs.

In some situations, it can be difficult, or even impossible, for the operator to see whether the reach forks are retracted or extended. This lack of visibility may lead to damage to the forklift or the warehouse racking.

To address this issue, the KOOI® ReachTrack system has been developed. Using a sensor, the system provides clear visual signals to indicate whether the telescopic forks are fully retracted, in motion, or fully extended.

This solution contributes to improved forklift safety, reduces the burden on the operator caused by limited visibility, and supports more efficient forklift operation overall.