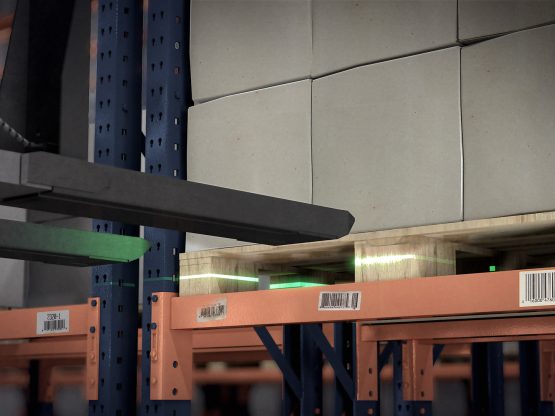

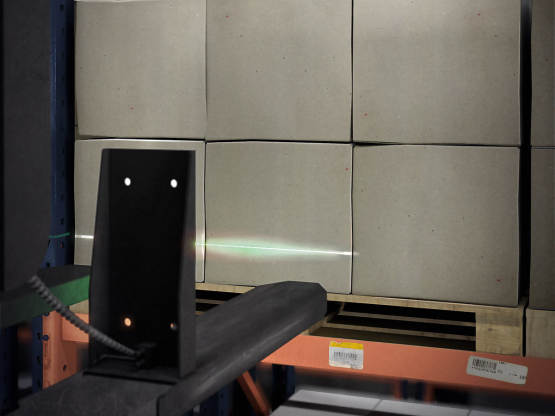

Green Laser Light:

– More visible in bright environments: Green light is up to five times more visible to the human eye than red light, especially in well-lit environments. This means the green laser beam is easier to see in brightly lit warehouses or when there’s significant sunlight.

– Better visibility over long distances: Green laser light retains its brightness over longer distances, making it ideal for warehouses with high-bay racking. Forklift operators can easily see the green laser beam, even when working at high elevations, improving accuracy when picking up loads.

Red Laser Light:

– Suitable for darker environments: Red laser light is more visible in low-light settings, such as warehouses with dim lighting or during evening hours. It is also a more cost-effective option compared to green lasers.

– Effective for shorter distances: While red light is less visible over long distances or in bright light, it remains effective for applications at lower heights or when working with pallets close to the ground.

The Difference Between Class 1 and Class 2 Lasers for Forklifts

In warehouse use, the main differences lie in safety standards and the risk of eye damage. Here’s an overview:

Class 1 Laser:

– Safety: Class 1 lasers are considered completely safe for direct eye contact under all reasonable use conditions, including prolonged exposure. This means the risk of eye damage is minimal, even if someone looks directly into the laser beam.

– Application: These lasers are often used in environments where safety is a priority and regular direct contact with the laser beam may occur, such as in automated systems or positioning lasers on forklifts. They are ideal for warehouses where many employees work close to the forklift.

Specifications:

Housing: Stainless Steel

ISO standard: Laser Class 1, ISO 60825

Laser color : Green

Ingress Protection: IP67

Service life: 30.000 hours