KOOI® DOUBLE DEEP STACKING

Meijer Handling Solutions has introduced a range of KOOI® Hydraulic Forks for narrow aisle forklifts that are ideal for double-deep pallet storage. Perfectly for double deep racking. This so called Single-Range is unique because each tine has its own cylinder, meaning that KOOI® ReachForks can be extended and retracted as fast as pantographs.

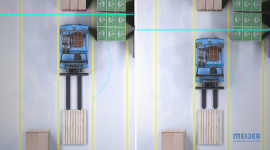

KOOI® Double deep stacking increases warehouse capacity by up to 30% compared to “single-deep” warehouse operations. Because KOOI® Telescopic Forks can reach almost twice as far as normal forks the warehouse racking at each side of the aisle can be doubled.

Contact

Do you want to know more about

KOOI® Double deep stacking applications?

KOOI® Double deep stacking

KOOI® Double deep stacking is mainly used on warehouse trucks like Reachtrucks and Articuladet fork lift trucks. These single-cylinder telescopic forks are ideal for double-deep pallet storage.

Double deep doesn’t require any specialist plant to operate except for a set of fork extensions, meaning that initial expenditure is kept low for plant to operate the system. Additional driver training for operators is not required and speed for access is higher than many other deep storage systems such as drive in.

Features and options

-

- Higher storage density by up to 30%.

- Efficient and easy to assemble.

- Last In First Out method of pallets

Advantages Of LIFO Method

- LIFO method is appropriate for matching cost and revenue.

- LIFO method is simple to operate and easy to understand.

- LIFO method facilitates complete recovery of material cost.

- LIFO method is most suitable when prices are rising.

Options: Deflection Measuring System, Fork Length Measuring System etc.

For more information : KOOI® Next

KOOI® ReachForks on VNA lift trucks

The “very narrow aisle” (VNA) permits greatest space use by making the passageways as little as could really be expected. Alongside high lift statures the restricted passageway framework offers high space usage particularly when utilizing KOOI® Telescopic Forks to have the option to store pallets double-deep in warehouses. By utilizing a camera fitted on the ReachForks outer sleeve (the moving part) the handling speed can be improved and harms diminished.

Specifications

Video

Brochure

40 years of experience

Meijer Handling Solutions was the first to develop a hydraulic extending and retracting lift truck fork.

Since their introduction in 1980, KOOI® ReachForks have become the benchmark in materials handling. With one and two cylinders in each fork and an integrated equalizer system, Meijer Handling Solutions guarantees you the best Telescopic fork on the market.

By using KOOI® ReachForks for double-deep stacking, storage volumes can be dramatically increased. Trucks and trains can also be completely loaded and unloaded from one side, reducing turnaround times and improving safety.

Additional advantages of the KOOI® ReachForks:

- Interchangeable wear resistant strips.

- Reinforced heel giving less deflection.

- Honed cylinder bores improve seal life.

- Hard chromed piston rods protected by outer forks.

- Specially designed wiper ring protects the forks even in dirty conditions.

- Special design fitting guard for easier connection of the forks onto the fork carrier.

- One or twin cylinders in each fork allow the forks to work in all kind of applications.

- Unique design outer forks includes integrated wear plate (400HB) for longer fork life.

- Fully integrated oil channels and hydraulic parts means working parts are protected reducing maintenance costs.

- An ingenious combination of laser cutting and sheet metal work construction ensures that sleeves do not catch when withdrawing from pallets. The sleeves corners are fully rounded off along all edges.

Double-deep ReachTrucks

The fact that the KOOI® ReachForks can reach twice as far as normal forks from one side means that the racking at each side of the aisle can be doubled.

KOOI® Double deep storage has become a very popular choice in “high throughput” operations and is ideal for Cold stores, Dry stores and the storage of multiple pallets of the same products, known as FILO (First In Last Out) principle.

KOOI® ReachForks are the best system for changing any type of forklift truck into a “double-deep” truck. The KOOI® Double deep stacking application has already generated considerable cost savings.

Telescopic forks can also have some important benefits in single-deep and double-deep applications. Compared to reach trucks with a pantograph reach mechanism or moving mast, the relatively light Telescopic forks result in a reach truck with better stability, visibility and higher lifting capacity.

Telescopic forks have some distinct advantages compared to a pantograph such as:

- Reduced attachment weight (approx. 35%).

- When using trucks with a fixed mast, it is no longer necessary to have a bottom racking beam, increasing ware house capacity and reducing overall racking costs.

- Virtually the same lost load thickness as standard forks and optimum visibility.

- Shorter mast compared to the total lift truck height.

- All parts are integrated inside the forks and cannot be damaged. Fewer items require maintenance, meaning reduced operating costs.

- Easy to install on new or existing lift trucks.

- Double pallet transport possible with same reach system.

When should u be using double-deep pallet stacking?

Pallets can be placed in a double deep configuration within a warehouse. This makes it possible to place two pallets from the same aisle, by placing one pallet to the rear of the rack and the other in front.

While the main advantage of the double-deep system (i.e. the ability to save space by requiring fewer aisles to access loads) is clear, we should also be aware of its limitations and requirements.

One of those limitations is that there is only direct access to the front pallet. To reach the second unit, the first pallet must be moved, or to its destination. Double deep stacking is related to FILO (first in, last out) inventory management.

If the customer also wants to store pallets at floor level, then a reach truck with a moving mast (entire mast moved forwards and / or backwards) with KOOI® ReachForks is the solution.

In a narrow aisle warehouse, the space is optimally used, with double-deep shelving, even fewer aisles are needed and the storage density is optimal. Double-deep stacking is possible thanks to the hydraulic telescopic forks mounted on a rotating fork carriage. The very narrow aisle truck (VNA) can pick up and store pallets on the left and right in the aisle.

Do you want to know more about our efficient handling solutions?