Kumatech Pallet Dispenser

For Meijer Handling Solutions, a Pallet Dispenser is a valuable asset because of the Pallet Transfer Machines they produce. A pallet dispenser is often necessary when changing pallets because pallets need to be added or removed. With the help of Meijer Handling Solutions, Kumatech has developed a fully universal basic pallet storage unit that can be expanded from 15 pallets to as many as 45 pallets. After an extensive testing period, including at the Meijer Group, this unit is proudly listed on the Meijer Handling Solutions website as a complementary product. Do you need more information, then please contact us.

Contact

Do you want to know more about

our Kumatech Pallet Dispenser applications?

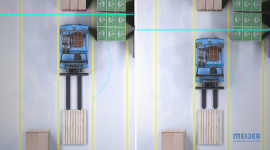

Vertical Pallet Warehouse

The Kumatech pallet dispenser is designed so that the customer can start small with a 15-pallet warehouse and if desired, a scale up to a 45-pallet unit without significant modifications. This is made possible by simply placing modules on the basic chassis. The Pallet Dispenser comes standard with all the usual safety features and is suitable for both manual and electric pallet trucks and or forklifts. The robust design has special bump ribs that protect the rear wall if the pallets are not driven in an orderly manner.

Benefits for the user

- Increases employee safety.

- No manual pallet handling.

- Reduces damage to pallets.

- Provides more overview and efficiency.

- Reduce time after finding and grabbing pallets.

- Contributes to a clean working environment.

- A professional appearance to visitors.

The above points gives a ROI of ± 1.5 years.

Features and Options

Standard features:

- Modular construction of 15, 30 to 45 pallets.

- Minimum / Maximum LED indicator.

- Main isolation switch

- Sensor control of eventual obstacles at insert side.

- Sensor control of correct pallet position.

Some options:

- Pallet dimensions other than Euro-pallets (1200x800mm).

- Handling of 1-5 pallets at a time.

- Cooperation with Kumatech AGV

- Picking up pallets from a trolley.

The main advantages of using a pallet dispenser include:

A pallet dispenser is a device used in warehouses, manufacturing facilities and logistics centers to automate the process of dispensing pallets. Its purpose is to efficiently and safely provide pallets for various material handling tasks, such as loading and unloading goods, storage and transportation.

- Pallet Organization:

- A pallet dispenser helps maintain an organized and neat storage area for pallets. It keeps the pallets stacked in a controlled manner, reducing the risk of pallets falling or creating obstacles in the workspace.

- Space Optimization:

- By utilizing vertical space, a pallet dispenser minimizes the footprint required for pallet storage. It enables stacking pallets vertically, thereby freeing up floor space and allowing more efficient use of the warehouse or facility.

- Streamlined Operations:

- The automated nature of a pallet dispenser speeds up pallet retrieval and reduces the time and effort required to manually handle and move pallets. This enhances overall operational efficiency and productivity.

- Safety and Ergonomics:

- Pallet dispensers enhance workplace safety by eliminating the need for manual lifting and handling of heavy pallets. Workers can retrieve pallets from the dispenser at an ergonomic height, reducing the risk of strain or injury.

- Flexibility:

- Pallet dispensers are adaptable and can accommodate different pallet sizes and types, including standard wood pallets, plastic pallets, or even custom pallets. This versatility allows for greater flexibility in handling diverse inventory requirements.

Overall, a pallet dispenser plays a crucial role in optimizing pallet management, enhancing operational efficiency, and promoting workplace safety within industrial and logistical settings.

Do you want to know more about our efficient handling solutions?