KOOI® FORKLIFT ATTACHMENTS THAT SAVE TIME, SPACE AND MONEY

Do you need efficient, smart and reliable intralogistics solutions?

WE ARE MEIJER HANDLING SOLUTIONS

Our company

We are the world’s market leader in hydraulic lift truck forks, known as KOOI® ReachForks. We are known for our palletless handling attachments KOOI® RollerForks, KOOI® Pallet Transfer System and safety enhancement for forklift trucks.

Our Goal

We aim to add value to our customers’ and end-users’ logistical supply chains. Our logistics products increase the ease of deployment and application of logistics/transportation resources, such as forklift trucks and their variants…

Latest news

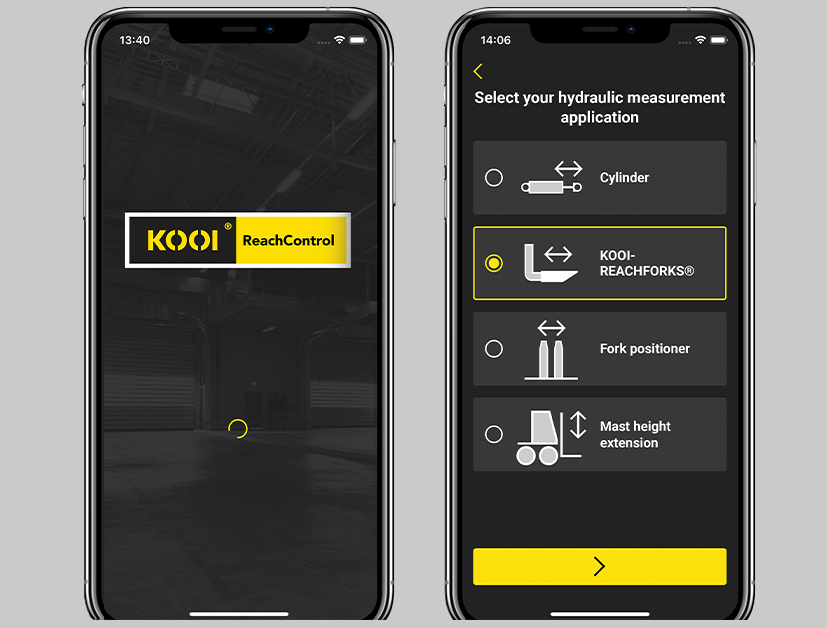

KOOI® ReachControl application available in App Store

Finally, we can proudly announce that our App for controlling the length measuring system for hydraulic forks is now available for download from the App store. The length measuring system is easy to install on forklift trucks and can be connected to… READ MORE

Do you want to know more about our efficient handling solutions?